Bare Bones Chocolate is made in our factory in the city centre of Glasgow – from bean to bar. Handcrafting the chocolate from cacao bean through to a finished bar allows us to control every step. We are so proud to be one of the very few UK producers who craft from bean to bar.

Cacao is one of the most complex, delicious and fascinating foods in the world. It is one of the few foods that is both fermented and roasted – creating unparalleled flavour profiles.

However, these incredible flavours have been mainly lost due to the demand for mass-manufactured industrial chocolate over the past century. Any large company is going to have different priorities than a small one, and for industrial chocolate, the priorities are consistency and low cost. Industrial chocolate may seem cheap but we are paying the cost in other ways. Each bar is full of unnecessary and harmful fats, e-numbers and additives – with often less than 20% cacao content.

We choose the best cacao beans from rare origins around the world and pay a premium price for them. Buying speciality cacao means paying far beyond the global market fair trade price. Paying for the worth of the cacao is so important in guaranteeing high-quality crops, creating a sustainable future for the farm and building a mutually beneficial relationship with the farmers. It’s not magic – an incredible chocolate bar starts with an incredible farmer.

Once the sacks arrive at our workshop, our process is long, with care taken at every stage:

We hand sort, assessing each bean individually for defects - beans that have defects/are badly fermented don’t taste as good. Sorting the good from the bad ensures that only the best beans are used.

Various chemical reactions occur within the cacao bean when it is roasted. We roast our beans in a modified coffee roaster in 5kg batches. We like to roast light and slow – to allow the sugars to caramelise in the bean and the natural flavours to develop. Our roaster allows us to control the heat input to the beans at each development stage, whilst rotating the beans to ensure each bean is evenly roasted - a level of control and consistency not achievable with oven roasting.

We then crack the roasted beans to separate the outer husk from the nibs using a modified grain mill. The nibs and husks are then separated by a process called winnowing.

We add nibs and a small percentage of cocoa butter to a heavy stone grinder called a melanger. We then add sugar and grind for up to 72 hours reducing the particle size of the ingredients. This 3-day process also works to mellow the chocolate, eliminating the volatile acids and bitterness commonly associated with dark chocolate.

We age our chocolate for 2-3 weeks to allow the flavours to develop further. Much like cheese or fine-wine, chocolate changes and enriches over time.

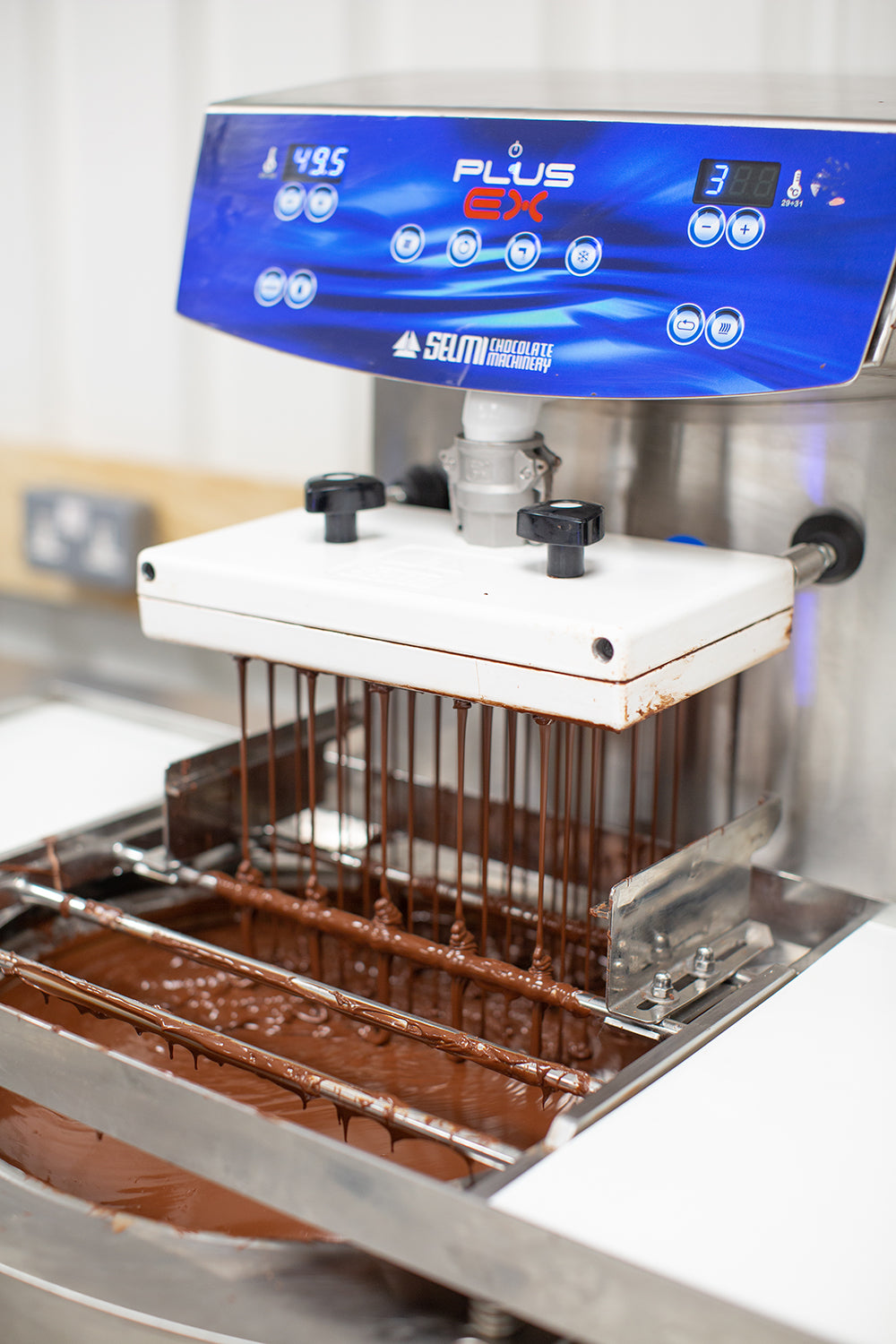

After ageing, we temper the chocolate, aligning its crystal structure to stabilise the chocolate and give it a crisp snap.

We wrap our bars by hand in Vegware compostable sheets, sealed with our signature 'Handcrafted in Glasgow' label. We then label, stamp and fold our boxes by hand. Our beautiful boxes are made from recycled coffee cups. All our packaging is from recycled sources and 100% recyclable or compostable after use.